This is Cinerama...at the London Casino |

Read more

at in70mm.com The 70mm Newsletter |

| Written by: W. G. Altria, Ideal Kinema, October 7, 1954 | Date: 09.01.2010 |

This

is Cinerama...at the London Casino. By W. G. Altria, Ideal Kinema,

October 7, 1954 This

is Cinerama...at the London Casino. By W. G. Altria, Ideal Kinema,

October 7, 1954Architects FRANK BAESSLER in association with T.,P. H., & E. BRADDOCK, F/ARIBA, M I Struct. E CINERAMA, which made its British debut in London last week, is a three-film system of wide-screen presentation. It is not stereoscopy; but the Cinerama camera exposes three films simultaneously, and the images are projected in synchronism on to a deeply curved screen, to give a picture covering a field of vision 146 deg, wide and 55 deg. high, and as this closely approximates to the field of human vision it creates an illusion of depth and reality which is enhanced by deep focus photography. The Cinerama camera has three 27-mm. lenses, set at angles of 48 deg. apart. Each lens takes one-third of the picture, recording it upon one of the three standard 35-mm. films. The axes of the lenses converge and cross at a point 11/16 in. in front; the left lens takes the right portion of the picture; the middle lens points straight ahead and takes the centre portion; and the right lens takes the left portion. The three films must, of course, be projected by three separate but electrically interlocked projectors, to produce the composite picture, and the projectors must be carefully orientated to correspond with the angles of the taking lenses. This necessitates the use of three widely spaced projection booths, one to the left of the auditorium to project the right-hand portion of the picture, one in the middle to project the centre portion and one on the right to project the left-hand portion. |

More

in 70mm reading: in70mm.com's Cinerama page Internet link: |

Click

image to see enlargement Click

image to see enlargementAbsolute mathematical accuracy must be maintained in positioning the projection rooms in relation to the screen to obtain accurate registration of the three pictures. To avoid" keystone effects the projector apertures must be lined up as near as is possible to the vertical centre of the screen. It is also essential that the audience should be seated with the eye level as near as possible directly opposite the screen; in other words, a steep angle of vision must be avoided. The London Casino Theatre was selected, after an exhaustive survey, as the best available in London for the showing of Cinerama. Nevertheless, considerable difficulties had to be overcome to make it entirely suitable for the purpose. |

|

One

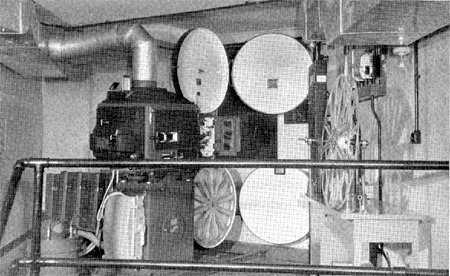

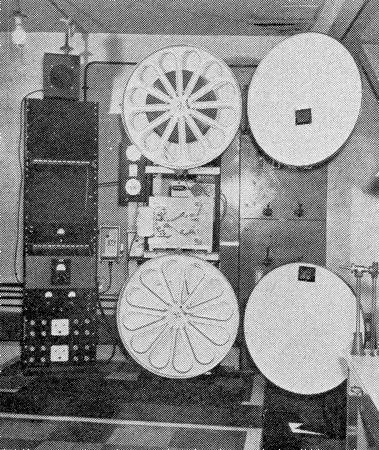

of the three Cinerama projection rooms installed at the London Casino. One

of the three Cinerama projection rooms installed at the London Casino.The British architects in charge of the installation had to send to their American colleague an accurate survey of the auditorium and other relevant sections of the theatre. From this information a set of drawings was prepared in America exactly setting out the position of the projectors, the size and curvature of the screen (which in this case is 64 ft. wide by 23 ft. high) and the ventilation and safety requirements according to American practice. The British architects then had to bring these into line with the requirements of the theatres section of the London County Council; this entailed considerable elaboration of the ventilation system and safety measure. In America, air can be drawn from the auditorium into the projection booths; in London, fresh air has to be trunked in from the outside of the building, and a mechanical extract system had to be provided with an outlet to the exterior of the building. The LCC insists upon separate exits from the projection rooms, each with a ventilated lobby, and isolated from the auditorium and public. These regulations necessitated more elaborate arrangements than are needed in America. |

|

The

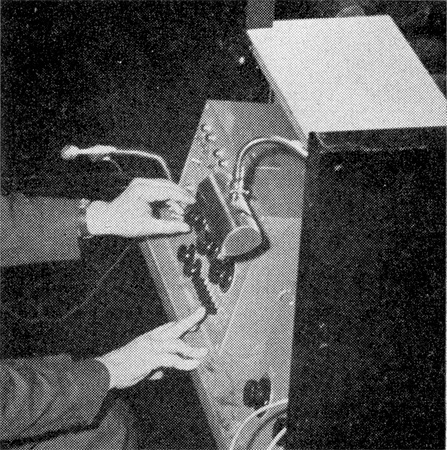

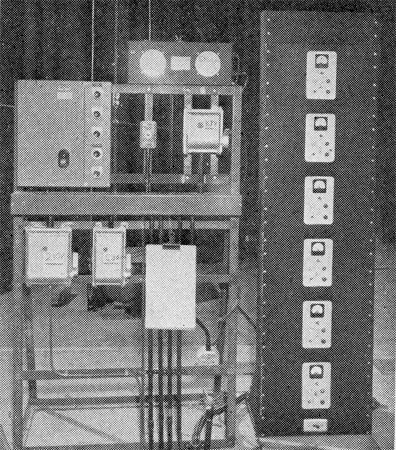

whole show is monitored from this control room in the auditorium. The

whole show is monitored from this control room in the auditorium.The problems arising from these requirements have been successfully overcome without a radical change in the appearance of the auditorium. It has been possible to retain nearly all the seating in the stalls level, where the projection booths had been installed; the circle seating remains unchanged, but part of the upper circle is not being used because of the steep angle of the sight-lines. Stereophony is regarded as an essential. A seven-track system is used. On the production side, five microphones are placed to pick up separate records of sound emanating from sources within the field of the camera. Up to three microphones may be used to the sides or rear of the camera position to record sounds from sources approaching, or leaving, the field of the camera. |

|

Magnetic

soundhead and pre-amplifiers. Magnetic

soundhead and pre-amplifiers.The seven tracks are re-recorded on to a separate magnetically coated film and are reproduced in the theatre by a soundhead, located in the normal projection room, and synchronised by an electrical interlock system with the Cinerama projectors. Five of the sound tracks operate five speaker assemblies behind the screen. The other two feed the auditorium effects speakers. The preamplifiers are in juxtaposition to the soundhead. Contrary to normal practice, the power amplifiers are located as near as possible to the speaker units-five backstage and the remainder in the projection booths. The sound system has been made specially to the Cinerama organisation's specifications. Technical data are not available for publication, but it is stated that the system is capable of handling a frequency range from 30 cycles up to 18,000 cycles, well into the upper harmonics. This compares with the 60-8,000 cycles frequency range of standard sound reproduction systems, and is indicative of the importance which the Cinerama designers attach to high-fidelity reproduction. |

|

Power

amplifiers for screen speakers. Power

amplifiers for screen speakers.Although the film used for Cinerama is of standard 35-mm. gauge the frame is higher than standard, extending over six sprocket holes instead of four. The three films, therefore, form a composite picture with an aspect ratio of nearly 3 to 1. The rate of projection of the images is 26 frames per second instead of the standard 24 per second. The projectors, made by the Century Projector Corp. of New York, a subsidiary of the Westrex Corp., basically are of standard design modified to the requirements of Cinerama. The mechanisms are geared, of course, for the appropriate intermittent motion, and the main drive motors are controlled by differential motors which provide a fine degree of adjustment so that the speeds of the projectors can be advanced or retarded to maintain the pictures in synchronism. An unusual feature is that the drive sprockets and guide rollers have spring-loaded flanges on one side to reduce the possibility of film weave in the gate. |

|

Interior

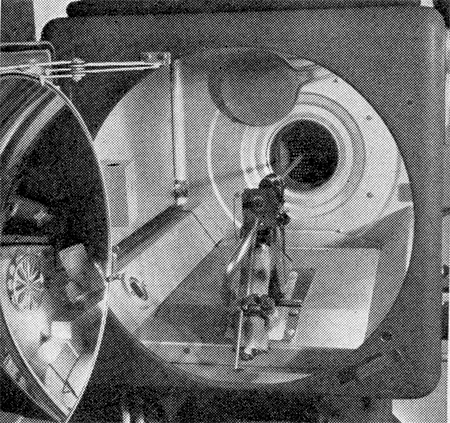

of one of the arcs. Interior

of one of the arcs.To overcome the problem of sharply defined joins between the three pictures the projector gates are fitted with vibrating saw-toothed masks at the sides of the aperture plates. There are three dowsers between the film and the arc lamp instead of the customary two. The extra dowser is the sync. dowser remotely operated from the main control console. In addition, the machines are equipped with water-cooled gates further to protect the film from over-heating and to reduce expansion of the gate when the oscillating mask plates are working. The Exelite arcs have motor-driven carbon-feed mechanisms, automatically controlled to maintain constant intensity of light. However, variations in the brilliance of the three pictures are liable to arise because of differences in the density of the three prints: even by modern processing standards it is difficult to obtain prints matched to the accuracy demanded by the Cinerama system. To compensate for this, metal gratings are interposed between the lamps and the gates. They are pivoted at the vertical centres, and when the gratings are moved away from the vertical, the angle of the slats to the axes of the light beams is changed, and this cuts down the amount of light passing through to the apertures. The gratings are actuated by servo motors for remote control. |

|

An

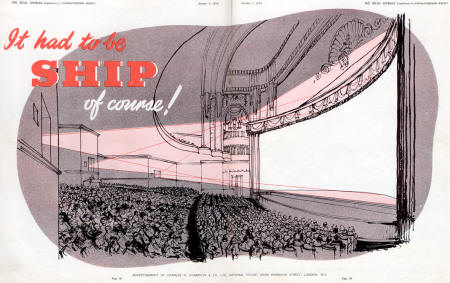

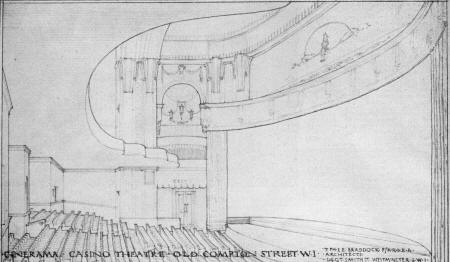

architects impression of the auditorium of London Casino. Parts of the three

projection rooms can be seen on the extreme left. An

architects impression of the auditorium of London Casino. Parts of the three

projection rooms can be seen on the extreme left.Click image to see enlargement. To minimise the width of the projection booths and encroachment upon seating accommodation in the auditorium, each booth is equipped with only one projector. If standard 2,000-ft. reels were used, seven stops would be required during each performance of the Cinerama programme, which runs for 110 minutes. To obviate this, the machines are fitted with magazines for 8,000-ft. reels and this enables the programme to be run through with only one short interval. The magazines have conventional fire traps and take-ups, but the spindles have been increased in size to sustain the additional load, and separate drive motors are used for take-up drive. In addition to the projector, each booth is equipped with a rewind machine capable of handling the 8,000 ft. reels. As the Cinerama films are on cellulose acetate base (safety stock) rewinding is permitted in the projection room; but not while the show is in progress. A separate room has been equipped for maintenance work on the films, including synchronising, cutting and splicing. |

|

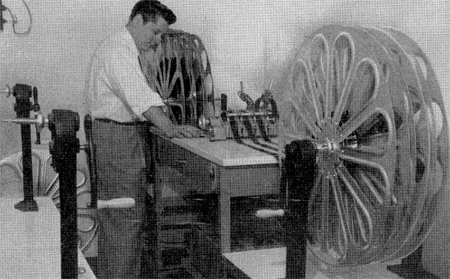

The

size of the 8000 ft spools can be seen in this picture of the maintenance

room, where any necessary synchronisation, cutting and splicing can be

carried out by the staff. The

size of the 8000 ft spools can be seen in this picture of the maintenance

room, where any necessary synchronisation, cutting and splicing can be

carried out by the staff.The Casino's original projection room has been re-equipped with Westrex British made standard projection and sound equipment. This is used for the showing of the prologue and for fill-in items in the event of a breakdown of the Cinerama programme. Centralised control of the complex array of equipment is absolutely essential. Provision is made for this in the master control console located immediately in front of the central projection booth. From this position the control engineer operates and monitors the entire performance. |

|

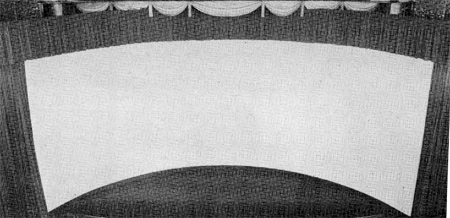

The

deep curvature of the 64ft by 23 ft screen is illustrated in the picture

above, taken from the upper circle, and in the picture below, which shows

the supporting framework and three of the speaker assemblies. The

deep curvature of the 64ft by 23 ft screen is illustrated in the picture

above, taken from the upper circle, and in the picture below, which shows

the supporting framework and three of the speaker assemblies.A series of green lights on the control panel indicates when the three projectors and soundhead are laced-up and in stationary synchronism. Switches are provided for operating the house lights and the screen curtain, and for starting and stopping the projectors and soundhead. A further series of red flashing lights gives a visual indication that the projectors are running in synchronism or otherwise. Below are individual controls for advancing or retarding the speed of the projectors so that they can be brought into step with one another, and the controls for regulating the brilliance of the three pictures. There is a master volume control, and facilities for varying the connections of the auditorium speakers to the effects tracks. Generally, one effects track operates the speakers on one side of the theatre and the other those on the opposite side. In certain sequences, however, the sound effects are required to move from the front to the rear of the auditorium or vice versa, and the control engineer manipulates the switching accordingly. An inter communication system is also provided for the transmission of verbal instructions between the control console and the booths and other points in the theatre. |

|

All

the Cinerama projection and sound apparatus was imported from America with

the exception of the speaker units. These are British-made by Westrex. All

the Cinerama projection and sound apparatus was imported from America with

the exception of the speaker units. These are British-made by Westrex.The vast curved screen is of unusual construction. The centre portion passes through an arc of 120 degrees, symmetrical about an axis, with tangent extensions, through an arc of 13 degrees, at each end of the centre portion. The total arc of the screen equals 146 degrees-the angle of photography of the Cinerama camera. The centre portion of the screen is made of a single piece of perforated material, similar to that used for standard screens, but the extensions at the sides are made of 7/8 inch strips of perforated material. The angular displacement and spacing of the strips are adjusted to avoid cross reflection of light between the side portions of the screen. |

|

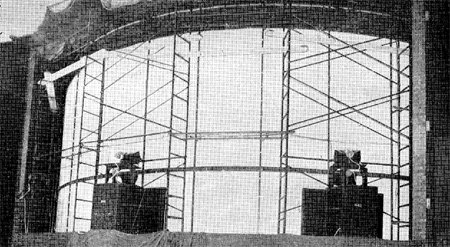

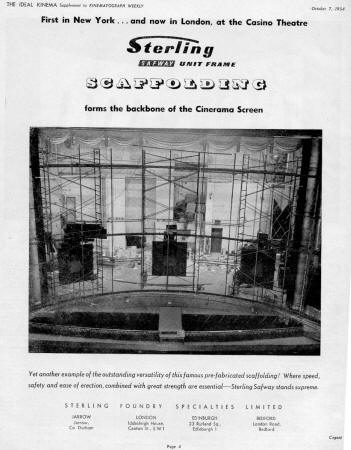

The

steel framework supporting the screen and ancillary equipment is the work of

two companies. Sterling Foundry Specialities, Ltd., supplied the series of

standard Sterling-Safway workstage towers, and the Unistrut metal framing

system marketed in this country by Sankey Sheldon, Ltd., is used to tie the

rowers together, and to support the loudspeaker assemblies, the screen and

the cantilevered frame-work for the screen masking, curtains and control

gear. The

steel framework supporting the screen and ancillary equipment is the work of

two companies. Sterling Foundry Specialities, Ltd., supplied the series of

standard Sterling-Safway workstage towers, and the Unistrut metal framing

system marketed in this country by Sankey Sheldon, Ltd., is used to tie the

rowers together, and to support the loudspeaker assemblies, the screen and

the cantilevered frame-work for the screen masking, curtains and control

gear. The Sterling Safway unit frame scaffolding is interchangeable with the American Safway, which has been a standard form of scaffolding in America for a number of years. Because of its strength and stability it has been used for all the Cinerama installations in America. |

|

Click

image to see enlargement Click

image to see enlargementIts advantages lie in it’s principles of built-in safety, the ease and speed with which it can be erected, and its exceptional load-bearing properties. The Unistrut metal framing system, introduced in 1939 by Mr. C. W. Attwood, an electrical contractor of Wayne, Michigan, but practically unobtainable until war-time material shortages ended, consists of a steel channel section, It in. square, cold rolled from 12 gauge material, available in 10 ft. or 20 ft. standard lengths. The channel is treated with a rustproofing material, and finished stove enamelled olive green. Hot dip galvanised finish is also available. In America the Unistrut system has been used in conjunction with the Safway towers for Cinerama and exclusively for a large number of CinemaScope screen frames. Building work and redecorations were carried out by C. E. Wilkinson, Ltd. For the three projection booths in the stalls reinforced concrete suspended floors are built on brick foundation walls. Above floor level the booths are constructed of foam slag block partitions plastered externally. The internal faces of the new partitions are clad in heavy duty Fibreglass quilt over which is fixed perforated asbestos sheets on a specially made metal trim. |

|

Click

image to see enlargement Click

image to see enlargementThe old ceilings have been removed and new suspended ceilings formed and covered with Fibreglass quilt and acoustic plaster board. The ventilated lobbies are constructed of clinker block partitions plastered on both sides. The company also was responsible for joinery and builders' work in connection with the ventilation plant. The Thames Bank Iron Company supplied and installed the ventilation system, with mechanical inlet and extract, for the three booths. There is an 18in. by 21in. centrifugal fan, with two ranges of galvanised ductwork connecting the booths with the outside of the building. The arc flues are connected to the extract ducts by flexible and lagged trunking. The electrical installation and wiring was carried out by the Strand Electric and Engineering Co., which also fitted the neon signs on the front of the building. |

|

Click

image to see enlargement Click

image to see enlargementFrom the intake at the rear of the theatre the supply is connected to two transformers of 400V input and 117V 10KVA single phase and 210V 30KVA output, respectively. Cables are run from the secondary side of the transformers to a main intake panel in one of the projection rooms and from here feeds supply the other projection booths. The supply for the arcs is obtained from selenium rectifiers, one in each booth. Ancillary work included wiring for new primary and secondary maintained lighting systems, ventilation fans, curtain motors, and auditorium speakers. In addition to the stage speaker systems there are two effects units on each side wall at front stalls and front circle level. There is also one unit in each of two theatre boxes at the rear of the stalls, with two similar units, connected in series, on the circle level. Ship plain HI rotating 10-mm. positive carbons and 8-mm. negative carbons are being supplied for the arcs. The uniforms for the male and female staffs were made by Uniform and General Services Co., Ltd. The colour scheme is navy blue. The male staff is supplied with smart tunic-style uniforms trimmed with gold, and the usherettes are dressed in tailored Eton-type jackets trimmed with gold, modern full-flared adjustable skirts, and white blousettes with black bow. The seating and carpets at the Casino supplied by W. W. Turner and Co. |

|

|

Go: back

- top - back issues

- news index Updated 22-01-25 |

|